Jawdah Molds & Spare Parts Factory has all the advanced capabilities that enable us to easily produce a wide range of complicated molds and spare parts. our factory has different manufacturing departments inside the factory each department contains the latest and most accurate industrial machines in the field of molds and spare parts.

5-Axis VMC provide a powerful combination of high speed & high accuracy, making them an extremely efficient, productive asset in the production. The multitask machining makes them ideal for process-intensive machining.

It is 4-axis VMC with additional Rotary axis has the capability of machining (Drilling Or Milling ) at any Machining Angle (0˚-360˚)for making special parts cannot be done with normal VMC like spiral Shafts.

3-Axis VMC is programmed by CNC programmer With CAM software ,this machine is the most important machine for Molds & Dies.

Turn/Mill Machine is capable of both rotating-work piece operations (turning) and rotating-tool operations such milling and cross-drilling, In addition to the live tooling, our machine in Jawdah is attached with Bar Feeder for manufacturing without any operator interruption which makes production much faster and products very accurate.

This lathe machine is programed by the operators finish the job faster and more accurately. It can make the same quality products with no deviation in production. We have more than one machine with senior operators.

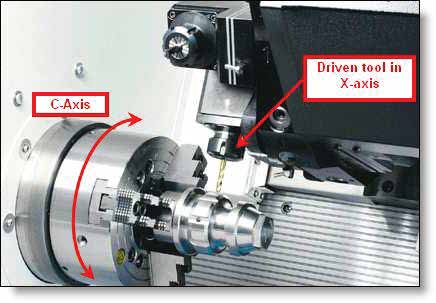

It is a CNC lathe machine with the ability to treat the spindle as another axis, called the C-Axis. This allows positioning the part with great accuracy for any angle to make complex parts that cannot be done on normal CNC lathe Machines.

Spark machining is a nontraditional method of removing metal by a series of rapidly recurring electrical discharges between the cutting tool (Electrode) and the work piece in the presence of a dielectric field.

This machine uses the same EDM concept with a metallic wire cut programmed contour in a work piece.

This machine uses electrode tube (Brass or Copper Material) to drill holes on electrically conductive material at a very high speed,where hole depth diameter ratio can reach up to 200 and hole diameter range from 0.3mm to 6.0 mm.

Grinding is used to finish work pieces by getting high surface quality (low surface roughness) and high accuracy of shape and dimension,this machine is used for Flat the surface of the work pieces.

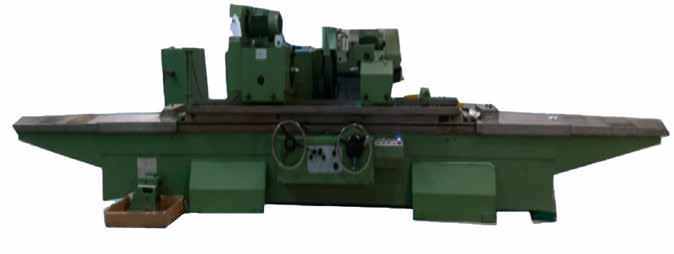

Cylindrical Grinding is used to finish work pieces by getting high surface quality (low surface roughness) and high accuracy of shape and dimension, this machine is used for Shaft & Cylindrical Shapes. We have two machines one for large diameters and one for small diameters.